LNG Refueling Station Product Information

LNG Refueling Station Product Information

Product introduction

Efficient and reliable liquefied natural gas refueling solutions for clean transportation

LNG refueling stations are available in two primary configurations: skid-mounted stations and permanent stations, meeting the needs of different application scenarios.

Permanent Refueling Station

All equipment is fixed and installed on-site at the station location, suitable for high-traffic, long-term refueling needs with higher processing capacity and storage volume.

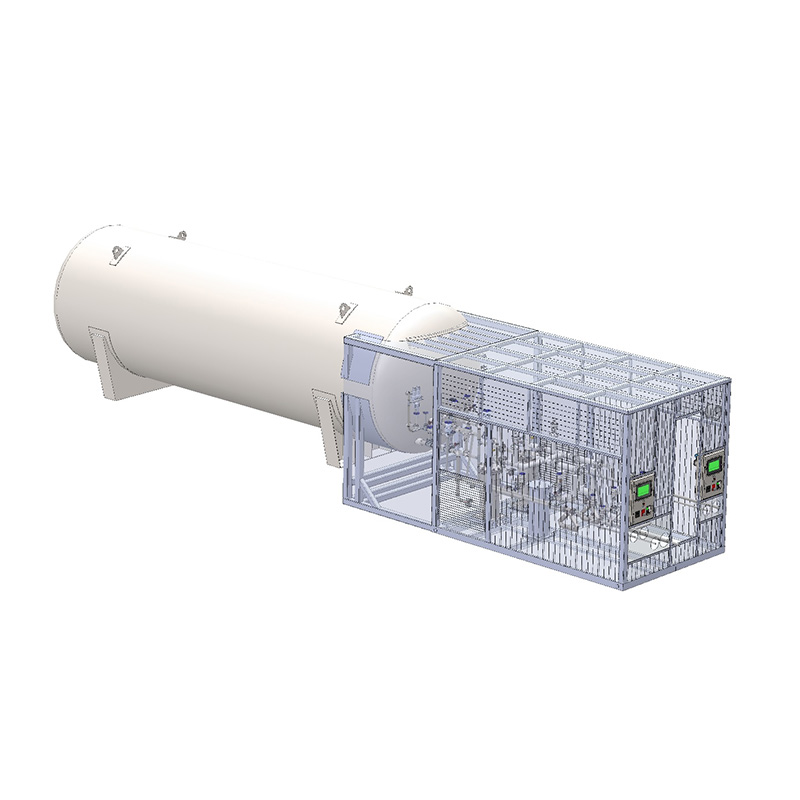

Skid-Mounted Refueling Station

All key equipment is integrated onto a single, transportable skid, offering high mobility and ease of installation, suitable for temporary or mobile refueling needs.

- Refueling Function: Transfer LNG from the station's storage tank to vehicle cylinders using a cryogenic pump for fast and safe refueling operations.

- Unloading Function: Receive and transfer LNG from delivery trailers into the station's storage tank, supporting various specifications of transport trailers.

- Pressure Boosting Function: Circulate and vaporize LNG, returning it to the storage tank to maintain or increase the pressure to the required operating level, ensuring refueling efficiency.

- Temperature Management: Circulate LNG from the storage tank through a vaporizer and back into the tank, adjusting the temperature to a preset value to maintain optimal conditions.

Overall Station Performance Parameters

- Refueling Capacity: 50-200 Nm³/h (customizable)

- Unloading Capacity: 60-180 m³/h (customizable)

- Refueling Pressure: 0.8-1.6 MPa

- Daily Refueling Volume: 3,000-30,000 Nm³/day

- Control System: PLC automatic control, remote monitoring

- Power Requirements: 380V/50Hz, 20-100kW depending on configuration

|

Component |

Technical Parameters |

|

LNG Storage Tank |

Capacity: 30-60 m³ (standard), up to 150 m³ maximum Working Pressure: 0.8-1.2 MPa Evaporation Rate: ≤0.3%/day Design Temperature: -196°C Insulation Method: Vacuum powder/multilayer winding Design Standard: GB/T 18442 / ASME |

|

Cryogenic Pump |

Flow Rate: 100-400 L/min (higher flow rates customizable) Outlet Pressure: 1.6 MPa (maximum) Power: 11-55 kW Material: Stainless steel (cryogenic grade) Sealing Method: Mechanical seal |

|

Air-Cooled Vaporizer |

Vaporization Capacity: 100-500 Nm³/h Design Pressure: 2.0 MPa Outlet Temperature: ≥-10°C Fin Material: Aluminum alloy Operating Environment Temperature: -30°C to 40°C |

|

Water Bath Vaporizer (Optional) |

Heating Capacity: 80-300 kW Outlet Temperature Control: 5-20°C Fuel: Natural gas/electric heating Thermal Efficiency: ≥90% |

|

Dispenser |

Flow Range: 5-60 kg/min Metering Accuracy: ±1.0% Working Pressure: 0.5-1.6 MPa Display: LCD touch screen with preset and totalizer functions Safety Features: Emergency stop, overpressure protection, breakaway coupling |

|

Piping System |

Design Pressure: 2.0 MPa Design Temperature: -196°C to 50°C Pipe Material: Stainless steel 304/316L Insulation: Vacuum pipe/polyurethane foam |

|

Control System |

PLC automatic control Remote monitoring and data transmission Safety interlocks and alarm management Compatibility: SCADA, IoT platforms Data recording and report generation |

- Multiple safety interlock protection system

- Emergency shutdown system (ESD)

- Combustible gas leak detection and alarm

- Flame detection and fire protection linkage

- Overpressure and overtemperature protection

- Lightning protection and static electricity grounding system

- Dual protection with safety valves and rupture discs

- Remote monitoring and diagnostic system

- Vehicle identification and management system

- Payment system integration

- Data upload to regulatory platforms

- Dual pump configuration (one working, one standby)

- BOG recovery system

- Explosion-proof rating upgrade

- Customized appearance design

mission

Efficient use of energy to improve the human environment

contact us

Since its establishment, our factory has been developing first world class products with adhering the principle of quality first. Our products have gained excellent reputation in the industry and valuable trust among new and old customers.